In order to simulate the working conditions of the SophiA refrigeration system in different climate zones, a small refrigeration cell instead of a 40-foot container is being set up in the laboratory of the University of Applied Sciences in Karlsruhe (HKA). Components are therefore placed outside the cell. The propane circuit is enclosed and ATEX-classified ventilation constantly draws in air to ensure safe operation. A plate heat exchanger acts as a propane condenser. By regulating the water mass flow, the condensing temperature can be adjusted to simulate different ambient temperatures to which the air condenser is exposed in Africa. Insulating panels divide the cell into +5°C and –30°C chambers. Electrical heating elements simulate the conduction of ambient temperature heat into the refrigerated container. The evaporator of the R744 cycle is housed in an enclosure with an innovative flap system. During the defrost cycle, the flap to the –30°C chamber is closed, while the flap to the +5°C room opens. In this way, defrosting removes heat from the room. A conventional freezer modified with an expansion vessel and an ethane compressor cools to –70°C, when placed in the -30°C chamber. During testing, high-pressure shutdown is achieved when the ambient air is at –25°C. To allow the operator of the cooling container a wider range of temperature settings, the ethane is mixed with a small amount of propane. New tests will show how the freezer performs with the new refrigerant, while the rest of the refrigeration cascade is being built.

Cooling Chamber

Water Treatment Technologies

Typically used for membrane bioreactors, the submerged ultrafiltration (UF) membrane module from SophiA partner Martin Systems GmbH produces hygienically safe drinking water by rejecting suspended organic and inorganic impurities. Ultraviolet (UV) radiation can keep the treated water disinfected for storage. The UF technology is demonstrated by Martin Systems’ 0.45 m2 Aqua Mini Cube and 6.25 m2 FM6 modules setup in the laboratory of HKA to filter water from model turbid suspension.

Figure 1. Ultrafiltration system with submerged Cube® FM 06 from Martin Systems GmbH setup in the laboratory of HKA University of Applied Sciences Karlsruhe (Photo Courtesy: Duc N. Dinh)

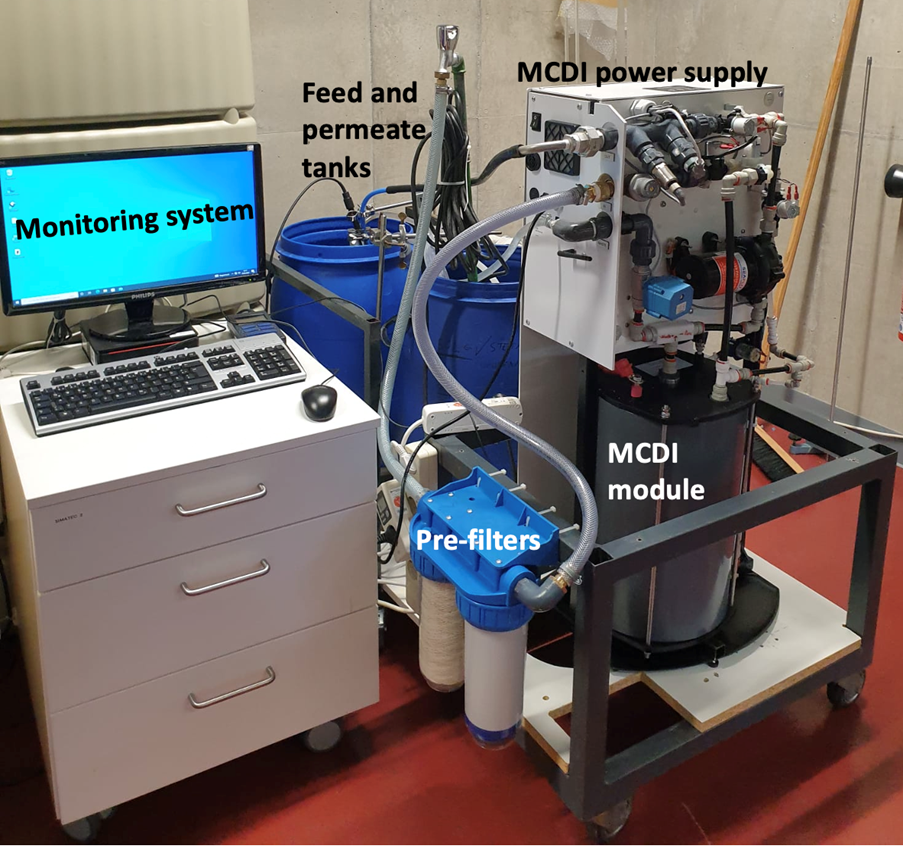

Typically used to treat brine solution, the membrane capacitive deionization (MCDI) technology is being studied at HKA to produce deionized water having conductivity below 20 µS/cm for steam production.

Figure 2. Membrane capacitive deionisation (MCDI) C12 module from Voltea INC setup in the laboratory of Hochschule Karlsruhe (Photo Courtesy: Paul Reis)